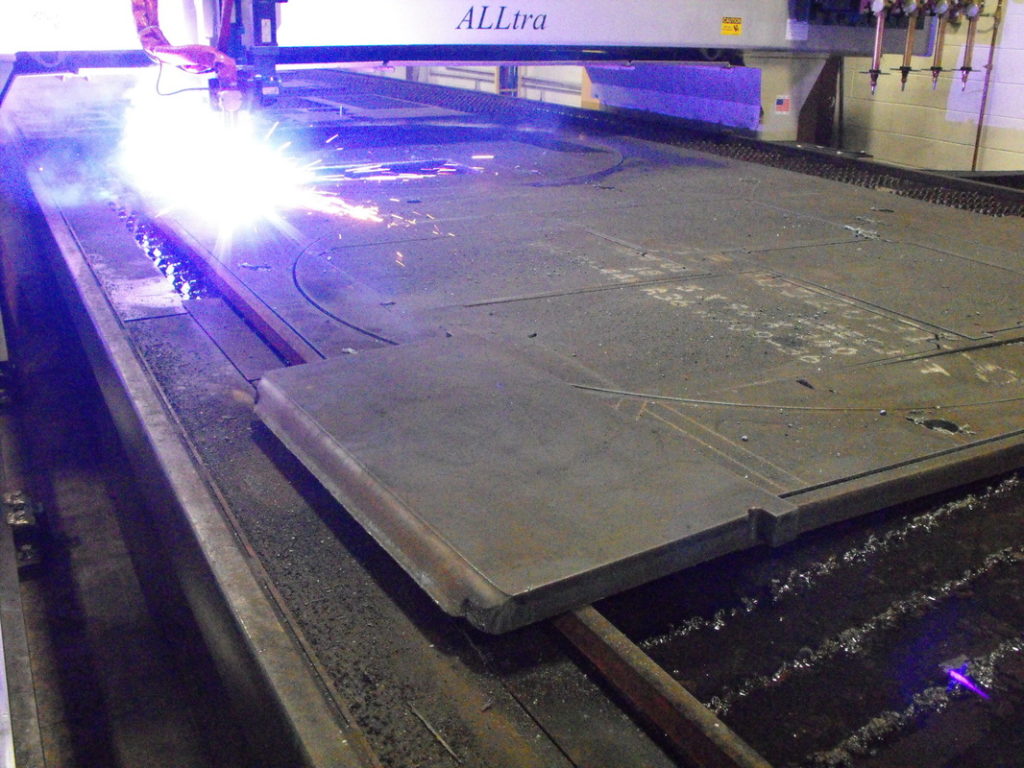

High-Definition Plasma Cutting Precision

Plasma cutting is one of the most reliable cutting methods used in metal fabrication. At W-Steel & Grinding, we have perfected the art of this time-honored technique. Leveraging decades of industry experience, we utilize plasma cutting to slice through carbon steel with remarkable precision, ensuring that our clients consistently receive superior results.

This process is crucial for industries that demand precise, clean, and consistent cuts. We take pride in delivering services that meet the highest standards.

At the core of our flame cutting process is the use of an oxygen-fueled flame that operates at extremely high temperatures to cut through thick metal sections. This approach allows us to handle a wide range of metal thicknesses, from relatively thin sheets to robust, heavy-duty steel plates. By adjusting the oxygen pressure, flame intensity, and cutting speed, our expert operators achieve optimal results for various types of projects.

Whether it’s producing large-scale structural components or detailed industrial parts, our team is trained to fine-tune the cutting process to meet the specific requirements of each job.

Why Choose Our Plasma Cutting Services?

1. High Precision and Clean Edges:

One of the most significant advantages of choosing W-Steel for your flame cutting needs is our ability to deliver high-precision cuts with sharp, clean edges. Our state-of-the-art flame cutting machinery is designed to ensure that each cut is smooth and precise, reducing the need for extensive post-cut processing. This means our clients save time and resources while receiving parts that are ready for the next stage of fabrication or assembly.

2. Efficient for Thick Materials:

Flame cutting is particularly advantageous for working with thick sections of carbon steel. Unlike other cutting methods that may struggle with large or dense materials, flame cutting excels in these scenarios. This efficiency allows us to undertake even the most demanding projects with confidence, ensuring that we can meet tight deadlines and high-volume requirements without compromising on quality.

3. Expert Operators and Custom Solutions:

Our team of highly trained operators brings unparalleled skill and attention to detail to every flame-cutting job. They are well-versed in optimizing all aspects of the cutting process-adjusting the flame, managing oxygen flow, and maintaining precise cutting paths to achieve the best possible outcome. This level of expertise means that we can offer custom solutions tailored to the unique specifications of each project, no matter the complexity.

4. Minimal Material Waste:

At W-Steel, we understand that material efficiency is crucial in metal fabrication. Our flame cutting services are designed to minimize material waste, making this process not only cost-effective but also environmentally responsible. By employing best practices and using advanced techniques, we ensure that our clients get the most out of their raw materials, maximizing value and reducing overall project costs.

5. Large-Scale Capability:

One of the reasons flame cutting remains a preferred method for many industrial applications is its ability to handle large-scale projects. At W-Steel & Grinding, we are equipped with high-capacity machinery that allows us to take on projects of significant size and scope. Whether it’s for the construction of large structural frameworks, heavy machinery components, or custom metal parts, our flame cutting services can meet the demand with ease and precision.

Applications of Flame Cutting in Various Industries

Flame cutting is a versatile process that serves a wide range of industries. In the construction sector, it is frequently used for creating structural steel beams, columns, and heavy-duty frameworks. The automotive and heavy machinery industries rely on flame cutting for producing durable parts that can withstand intense usage and stress. Additionally, the energy sector often turns to flame cutting for the fabrication of robust components used in power plants, oil rigs, and renewable energy installations.

At W-Steel & Grinding, we understand the unique demands of these industries and work closely with our clients to ensure that each project is executed to their exact specifications. We are committed to providing solutions that not only meet but exceed the rigorous standards set by the industry.

Commitment to Quality and Customer Satisfaction

What sets W-Steel apart is our unwavering commitment to quality and customer satisfaction. Every flame cutting project we undertake is approached with the same level of care and attention to detail. From the initial consultation to the final inspection, we prioritize clear communication and a collaborative approach, ensuring that our clients remain informed and confident throughout the process.

Our quality control measures are stringent, with each cut being thoroughly inspected to guarantee that it meets both our standards and those of our clients. We believe that reliability is built on trust, and we work tirelessly to maintain that trust by delivering consistent, high-quality results.

Why W-Steel & Grinding?

With over three decades of experience and a reputation built on excellence, W-Steel & Grinding has become a trusted name in fabrication. Our flame cutting services embody this legacy, offering the reliability, precision, and efficiency that our clients have come to expect. Whether you are looking for a partner to handle high-volume production or a complex, custom job, we are equipped to provide solutions that meet your specific needs.

Choose W-Steel & Grinding for your flame cutting projects and experience the difference that expertise, dedication, and quality can make. We stand by our mission to be “solid as steel,” delivering results that you can count on-every time.