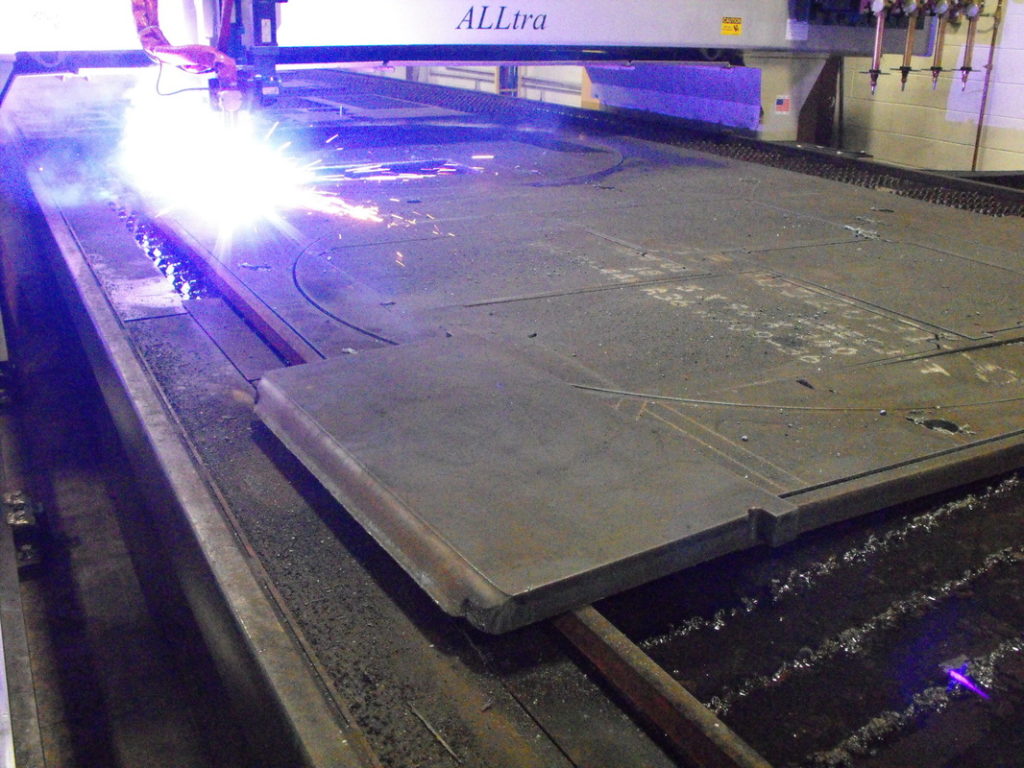

Flame Cutting

Flame cutting is the process of that is used for cutting mild steel. During flame cutting, oxygen is used to cut the steel by blowing oxygen into the kerf at 100 psi. This causes the metal to heat and react with oxygen to make the metal burn and oxidize.

- ALLtra multi-torch flame-cut table – CNC

- 11ft x 44ft water table (10ft x 40ft plate)

- Typical plate stock: A36: 1/8” to 9” plate

- 1045, Freemax & 4140 alloy

- Bar stock: A36 flat & squares, rounds

- Structural: round & square tube, pipe, channel, I-beam

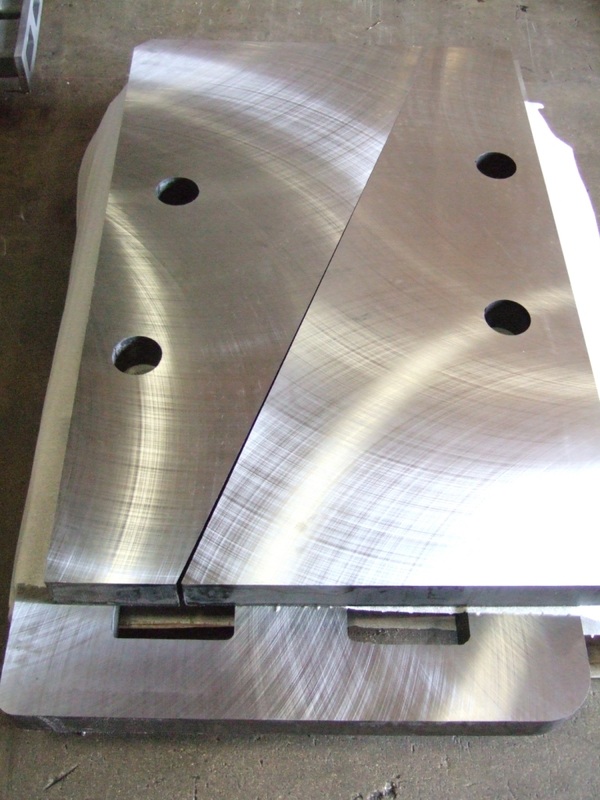

Plasma Cutting

Plasma cutting is a type of process that is used to cut steel or other metals by using a plasma column of electrically charged gas creates a high-energy arc, which melts the material being worked in a narrow path. Bevels can be added into to the part as it is being cut from the plate in one operation with the 5 axis plasma torch, this includes inner and outer radius and OD/ID parts.

- ALLtra high def plasma (400 amp – cuts up to 1-1/2” thick, robotic bevel head)

Welding & Fabrication

- Welding of A36, 1045, 4140, 316 SS, aluminum

- Custom fabrication of fixtures, bases, machines, and weldments

- Straightening

- Stress relieving & sandblasting

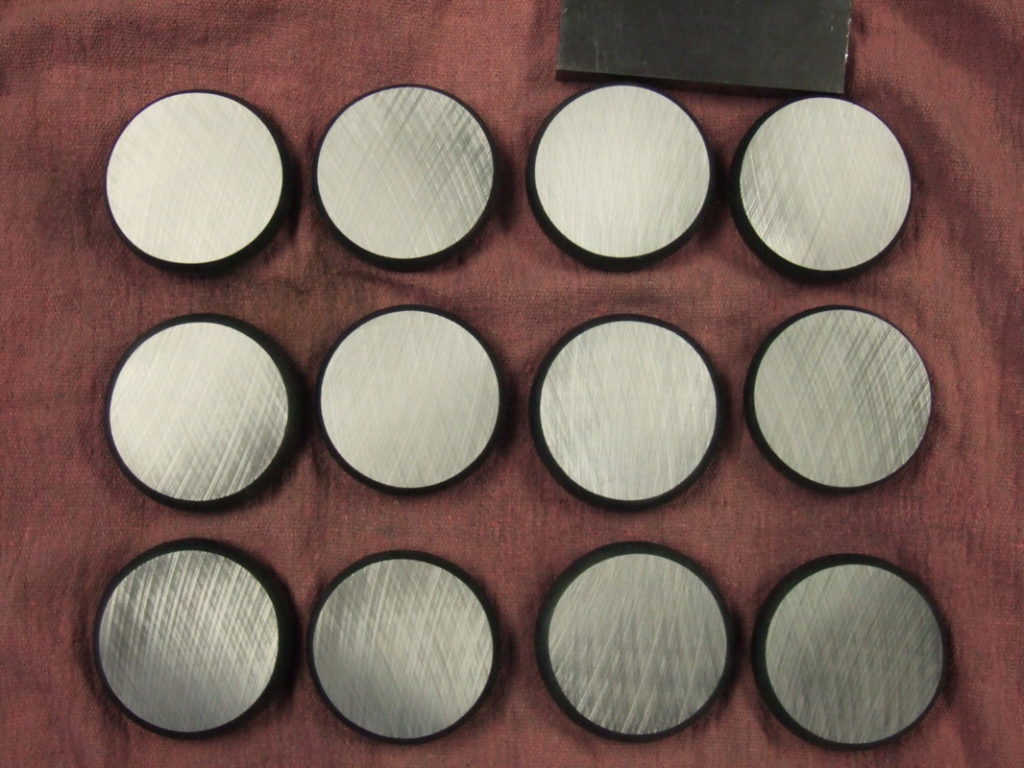

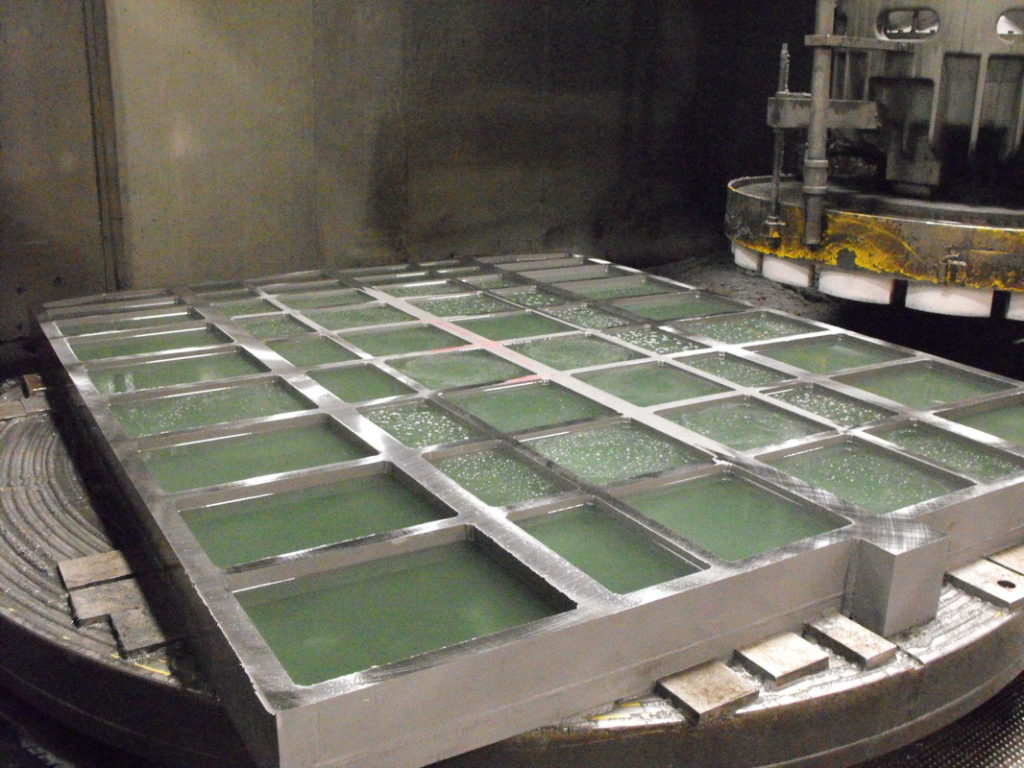

Blanchard Grinding

Blanchard grinding, technically referred to as rotary surface grinding, quickly removes stock. Typically, ferrous metals are subjected to the Blanchard grinding process, since the part is often held in place by a magnetic chuck as it is ground.

Blanchard grinding leaves a specific finish pattern on surfaces, produced by the nature of the operation, and of the movement of grinding tools across the surface. Technically referred to as rotary surface grinding, the process is ideal for surfaces too large for disc grinding, such as plate stock, die blocks and rotary tables.

Although it uses far more horsepower than other grinding services, turnaround time is much faster for certain parts; the process can be used simultaneously on multiple parts, as well, also leading to reduced production times and expense.

- Quality grinding of plates, weldments, castings, and die sets

- Specialize in close tolerance grinding of four and six-sided parts

- Twelve Blanchard grinders under power; 36”, 42”, 60”, 100” & 120”

- Maximum swing of 154”, with 60” of vertical height