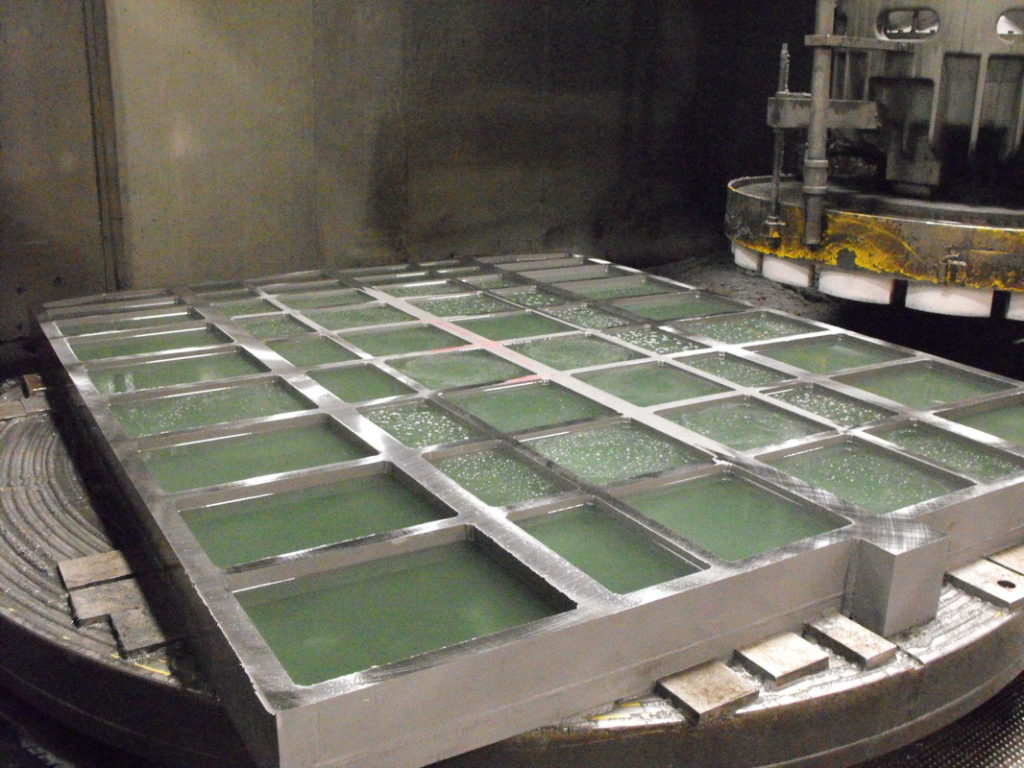

At W-Steel & Grinding, our Blanchard grinding services are designed to deliver efficient and uniform grinding, achieving a high-precision finish on both large and small parts. This process, also known as rotary surface grinding, utilizes a vertical spindle and a rotating magnetic chuck to grind large surfaces with unmatched efficiency. Blanchard grinding is particularly suited for quickly removing stock from parts, resulting in a high degree of flatness and parallelism that traditional grinding methods may not achieve as effectively.

High-Capacity Equipment for Diverse Needs

One of the standout features of our Blanchard grinding capabilities is our state-of-the-art machinery, which can accommodate parts of various sizes and dimensions. This flexibility allows us to serve a wide range of industries, from tool-and-die manufacturers and heavy equipment producers to automotive and aerospace clients. Our grinding equipment is built to handle parts as small as precision components or as large as machine bases, die blocks, and structural elements. This versatility ensures that we can meet the needs of clients who require a reliable grinding process to achieve uniform thickness across large surface areas.

Uniform Finish & Precision

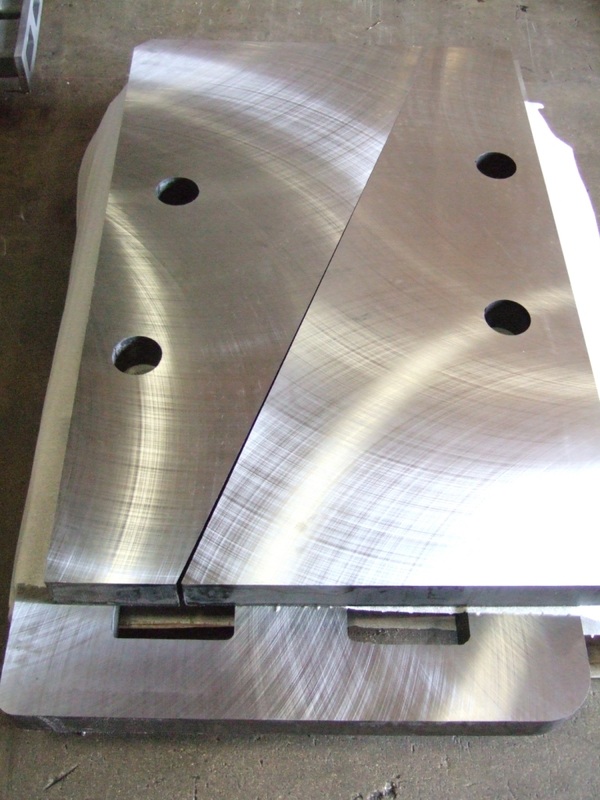

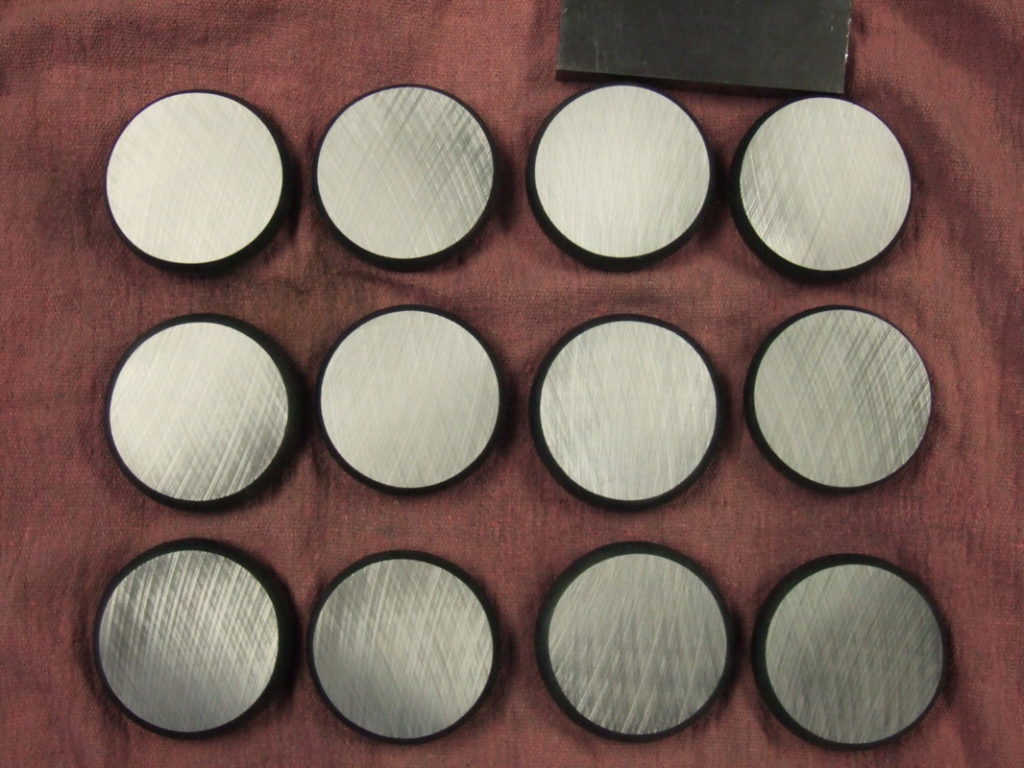

The hallmark of Blanchard grinding is the distinctive cross-hatched pattern it leaves behind, which signifies a uniform and consistent finish. This technique is known for producing surfaces with a high level of accuracy, making it a preferred choice for parts that require tight tolerances and a flat, smooth surface. Whether it’s for enhancing the aesthetics of a part, preparing it for further machining, or ensuring parallel surfaces for better assembly and performance, our Blanchard grinding services meet and exceed industry standards for quality and precision.

Skilled Technicians and Quality Assurance

At W-Steel, we understand that the success of our Blanchard grinding services depends on both the equipment and the expertise of our team. Our highly trained technicians bring years of experience to every project, ensuring optimal machine setup, operation, and quality control.

From selecting the appropriate grinding wheel grit and setting precise feed rates to carefully monitoring the process for consistent results, our team takes pride in achieving superior finishes that align with client specifications.

Each project goes through rigorous inspection and quality assurance measures to verify flatness, parallelism, and overall quality. This attention to detail is what allows us to confidently deliver products that meet even the most stringent industry standards.

Applications Across Industries

Our Blanchard grinding services are widely used across industries for various applications. In the tool-and-die industry, precision grinding is essential for preparing die blocks and plates with perfectly parallel surfaces, ensuring that they perform seamlessly in production. Machine builders rely on Blanchard grinding for creating perfectly flat and even machine bases and components that form the foundation of their equipment. For the aerospace sector, the ability to produce parts with consistent thickness and minimal variations is critical for ensuring that components fit together with precision, enhancing safety and performance.

Stock Removal & Surface Preparation

One of the main benefits of Blanchard grinding is its effectiveness in rapid stock removal, making it an ideal choice for jobs that require significant material to be removed from both sides of a part. This efficiency not only saves time but also reduces overall production costs by allowing for quicker turnarounds and less manual labor. Our Blanchard grinding services are often used as an initial step to prepare a part for secondary processes and for finished machining. The result is a flat, uniform surface that is perfect for further machining or finishing.

Handling Complex Specifications

Complexity is not a barrier at W-Steel. We specialize in custom solutions that adhere to specific client requirements, whether that means grinding to unique dimensions or achieving a surface finish that meets exacting tolerances. Our experience working with a range of materials, from high-strength carbon steel to stainless steel and other specialty alloys, allows us to tailor our grinding approach to the particular needs of the project. Clients can rest assured that we have the expertise to address unique challenges and provide solutions that maximize the functionality and durability of their components.

Commitment to Customer Satisfaction

Client satisfaction is at the heart of what we do at W-Steel. Our reputation has been built on reliability, precision, and dedication to service. We maintain open lines of communication throughout each project, keeping clients informed of progress and collaborating closely to address any specific requirements or concerns. Our ability to deliver consistent, high-quality results has earned us the trust of clients who continue to return to us for their metalworking needs.

Why Choose W-Steel for Blanchard Grinding?

Choosing W-Steel for Blanchard grinding services means partnering with a team that prioritizes quality, efficiency, and precision. Our commitment to investing in advanced machinery and ongoing staff training ensures that we stay at the forefront of the industry, capable of handling projects of varying complexity and size. With decades of experience and a proven track record, we offer reliable grinding solutions that cater to both high-volume production runs and custom one-off projects.

If you’re looking for exceptional Blanchard grinding services that emphasize precision, speed, and top-tier customer care, look no further than W-Steel & Grinding. Contact us today to discuss your project needs and discover how we can provide the best grinding solutions tailored to your requirements.